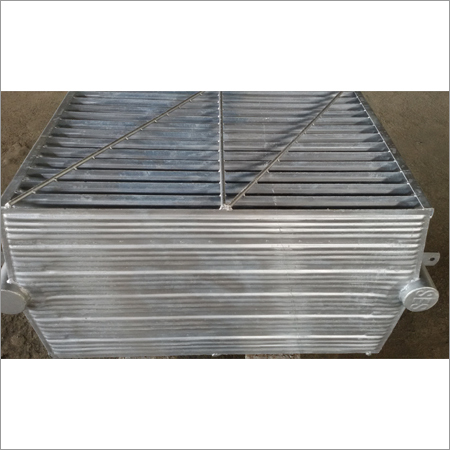

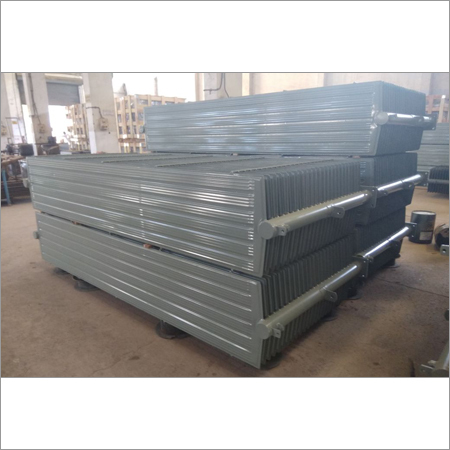

Hot Dip Galvanised Radiator

Price 20000 INR/ Piece

MOQ : 40 Pieces

Hot Dip Galvanised Radiator Specification

- Usage

- POWER / DISTRIBUTION TRANSFORMERS

- Material

- CRCA

- Central Distance

- 1000-2000 Millimeter (mm)

- Height

- 1400 Millimeter (mm)

- Working Pressure

- 2 kgf/cm2

- Length

- 1000-2000 Millimeter (mm)

- Width

- 300 / 520 Millimeter (mm)

Hot Dip Galvanised Radiator Trade Information

- Minimum Order Quantity

- 40 Pieces

- FOB Port

- POR, VADODARA

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cheque

- Supply Ability

- 50 Pieces Per Month

- Delivery Time

- 30-40 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- STANDARD WOODEN CRATE PACKING DONE AS PER REQUIREMENT OR NECESSITY.

- Main Export Market(s)

- Middle East, Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About Hot Dip Galvanised Radiator

We have been a noted manufacturer of Hot Dip Galvanised Radiator in the market. It is designed for eliminating any possibility of distortion even in 1mm thick radiators. We precisely fabricate this using tested grade raw material sourced from our trusted vendors. This material is processed at our state-of-the-art unit under the professional guidance. Hot Dip Galvanised Radiator is inspected on several parameters before dispatching from our unit to make sure that the industrial standards are efficiently and effectively met.

Superior Cooling for Transformers

Engineered to meet demanding power and distribution transformer requirements, these hot dip galvanised radiators ensure excellent cooling efficiency and operational stability. Precision manufacturing and strict quality checks mean reliable heat dissipation, even under prolonged or heavy transformer loads.

Corrosion Resistance and Longevity

Constructed from high-grade CRCA and coated through the hot dip galvanisation process, these radiators provide outstanding resistance against rust and environmental wear. Their robust build and protective finish deliver a longer operational life, reducing maintenance needs and downtime for users.

Adaptable Dimensions for Versatile Applications

Available in lengths from 1000 to 2000 mm, height of 1400 mm, widths of 300 or 520 mm, and matching central distances, these radiators are compatible with a wide range of transformer designs. This flexibility ensures seamless integration into new or existing transformer installations.

FAQ's of Hot Dip Galvanised Radiator:

Q: How is the hot dip galvanisation process carried out for these radiators?

A: The hot dip galvanisation process involves immersing the CRCA radiator panels in molten zinc, forming a tough, corrosion-resistant coating. This protects the radiator against rust and environmental damage, ensuring long-term reliability in power and distribution transformers.Q: What are the main benefits of using a hot dip galvanised radiator in transformers?

A: The key benefits include superior corrosion resistance, extended service life, and improved transformer cooling performance. This leads to reduced maintenance costs, greater operational efficiency, and enhanced reliability of transformer systems.Q: Where are these radiators typically used?

A: These radiators are specifically designed for use in power and distribution transformers, providing essential cooling to prevent overheating and maintain consistent transformer performance across various industrial, utility, and commercial settings.Q: When should a transformer radiator be replaced or upgraded?

A: Radiator replacement is recommended when there are signs of leaks, reduced cooling efficiency, corrosion, or mechanical damage. Upgrading to a hot dip galvanised model is also advisable during transformer refurbishment or when operating conditions demand greater durability.Q: What is the recommended working pressure for these radiators?

A: These hot dip galvanised radiators are designed to operate efficiently at a working pressure of 2 kgf/cm2, making them suitable for conventional transformer cooling requirements.Q: How do the dimension options ensure compatibility with different transformers?

A: With length options from 1000 to 2000 mm, a standard height of 1400 mm, and widths of 300 or 520 mm, these radiators can fit a wide array of transformer models, offering flexibility for tailored installations or replacements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Transformer Radiators Category

520 mm Width flange type Radiator

Price 10000.0 INR / Piece

Minimum Order Quantity : 12 Pieces

Material : CRCA

Working Pressure : 2 kgf/cm2

Central Distance : 7003500 Millimeter (mm)

Usage : POWER / DISTRIBUTION TRANSFORMERS

OFF CENTER RADIATORS

Price 50000.00 INR / Set

Minimum Order Quantity : 1 Piece

Material : Highgrade Steel

Working Pressure : 0.6 MPa

Central Distance : 500 mm

Power Transformer Radiator

Price 25000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : CRCA

Working Pressure : 2 kgf/cm2

Usage : Industrial

520 mm Width Swan Neck Type Radiator

Minimum Order Quantity : 16 Pieces

Material : CRCA

Working Pressure : 2 kgf/cm2

Central Distance : 1000 to 3500 Millimeter (mm)

Usage : Transformers

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS