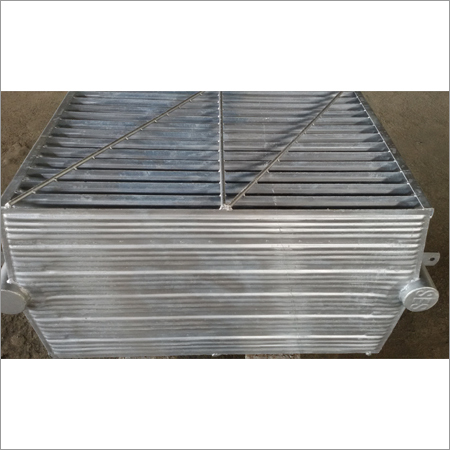

520 mm Width Swan Neck Type Radiator

Price 4000.0 INR/ Piece

520 mm Width Swan Neck Type Radiator Specification

- Usage

- Transformers

- Material

- CRCA

- Central Distance

- 1000 to 3500 Millimeter (mm)

- Working Pressure

- 2 kgf/cm2

- Width

- 300 / 520 Millimeter (mm)

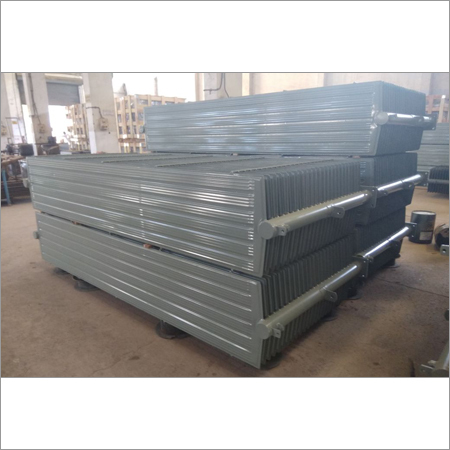

520 mm Width Swan Neck Type Radiator Trade Information

- Minimum Order Quantity

- 16 Pieces

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Cheque

- Supply Ability

- 30 Pieces Per Month

- Delivery Time

- 7 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- With Standard wooden crate packing

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About 520 mm Width Swan Neck Type Radiator

We offer a premium quality range of 520 mm Width Swan Neck Type Radiator in the market. This is sturdily fabricated using superior grade material and modern machinery in sync with set industrial norms and standards. 520 mm Width Swan Neck Type Radiator is known for its high efficiency, easy installation, low maintenance and better durability. This makes it stand apart from other radiators in the market. We offer this at highly pocket- friendly prices within a stipulated period of time.

Features :

- Center Distance: 800mm to 3500mm

- Width of Fin: 226 / 300 / 375 / 520mm

- Pitch: 50 / 75mm

- Pipe OD: 60 / 75 / 89 mm

| Material | Stainless Steel |

| Phase | Three Phase |

| Shape | Rectangular |

| Usage/Application | Industrial |

| Corrosion Resistant | yes |

| Surface Treatment | metal finish |

| Country of Origin | Made in India |

| Width of Fin | 226-300-375-520mm |

| Pipe OD | 89 -114mm |

Precision Engineering for Transformer Cooling

Our Swan Neck Type Radiators, available in 520 mm width variants, are meticulously designed to deliver optimal thermal performance in transformers. The use of CRCA material guarantees enhanced strength and resistance to environmental factors, while the wide range of central distances ensures flexible installation. These radiators maintain efficient heat dissipation, ensuring transformer longevity and operational safety.

Versatile Dimensions and Applications

With options ranging from 300 to 520 mm width and central distances between 1000 to 3500 mm, our radiators cater to various transformer sizes. Their robust build and compatibility make them suitable for use in power distribution and industrial transformer applications across India.

FAQ's of 520 mm Width Swan Neck Type Radiator:

Q: How does the 520 mm Swan Neck Type Radiator enhance transformer cooling efficiency?

A: The 520 mm Swan Neck Type Radiator offers optimized surface area and fluid circulation, which improves heat dissipation from transformers. This efficiency in cooling helps maintain stable transformer temperatures, ultimately extending equipment life and ensuring reliable performance.Q: What is the process of manufacturing CRCA Swan Neck Type Radiators?

A: Our Swan Neck Type Radiators are manufactured using cold-rolled close annealed (CRCA) steel. The process involves precision cutting, shaping, welding, and forming to achieve the unique swan neck profile, followed by stringent quality checks to ensure pressure integrity and long-term durability.Q: When should I use a Swan Neck Type Radiator for my transformer?

A: A Swan Neck Type Radiator is ideal when your transformer requires dependable cooling under a controlled pressure environment (2 kgf/cm2) and needs customized width or central distance to fit specific installation layouts, particularly in industrial or utility-scale transformers.Q: Where are these radiators typically installed?

A: These radiators are predominantly installed in transformer stations and substations in India, providing cooling solutions for power distribution and transmission transformers in both rural and urban domains.Q: What are the main benefits of using CRCA material in radiator construction?

A: CRCA material offers superior strength, corrosion resistance, and smooth finish. These attributes enhance the radiator's durability, improve heat transfer efficiency, and ensure low maintenance requirements, making it suitable for demanding transformer applications.Q: How can I select the correct central distance for my transformer's radiator?

A: To determine the appropriate central distance, assess your transformer model's dimensional requirements and intended installation space. Our adjustable options (from 1000 to 3500 mm) allow for easy customization, ensuring a precise fit and straightforward integration.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Radiators Category

520 mm Width flange type Radiator

Price 10000.0 INR / Piece

Minimum Order Quantity : 12 Pieces

Material : CRCA

Working Pressure : 2 kgf/cm2

Usage : POWER / DISTRIBUTION TRANSFORMERS

Central Distance : 7003500 Millimeter (mm)

Hot Dip Galvanised Radiator

Price 20000.0 INR / Piece

Minimum Order Quantity : 40 Pieces

Material : CRCA

Working Pressure : 2 kgf/cm2

Usage : POWER / DISTRIBUTION TRANSFORMERS

Central Distance : 10002000 Millimeter (mm)

OFF CENTER RADIATORS

Price 50000.00 INR / Set

Minimum Order Quantity : 1 Piece

Material : Highgrade Steel

Working Pressure : 0.6 MPa

Central Distance : 500 mm

Power Transformer Radiator

Price 25000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : CRCA

Working Pressure : 2 kgf/cm2

Usage : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS